Refinery gas treatment

Refineries are designed to process crude oil streams into a wide variety of valuable products including gasoline, diesel, kerosene, LPG, waxes, and more. Most crude oil streams are sour, containing a percentage of organic sulfur species that are not tolerable in the product streams. The most effective process for removal and disposal of the sulfur components is conversion to hydrogen sulfide (H2S) and subsequently elemental sulfur via the Claus process.

Processes:

Products:

Requirements:

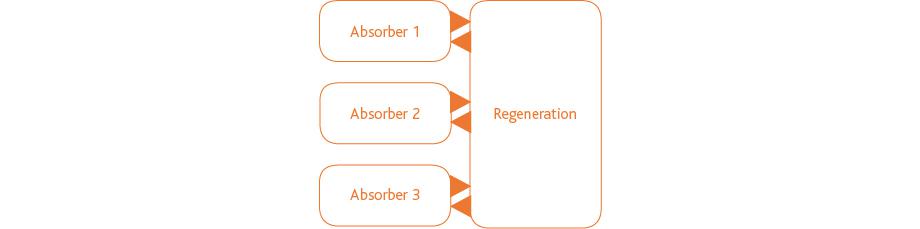

Processes such as hydrotreating are specifically designed to convert undesirable sulfur into H2S. Other units, such as catalytic crackers and hydrocrackers, also produce streams containing H2S. Other gas streams, such as the gas from catalytic cracking, may also contain CO2. Refineries widely rely on a distributed amine system with dedicated absorbers for the various sour gas and liquid hydrocarbon streams and a common regeneration section. The absorber design and amine solvent selection are typically geared toward total sulfur removal and partial CO2 removal.

Challenges

Refinery systems suffer from typical, corrosion-induced refinery gas contaminants such as hydrogen cyanide.

Eastman’s answer

Eastman’s technical services team can help by identifying contaminants, carrying out root-cause analysis, and providing recommendations for remediation of the problems. Learn more about our technical services here.

Eastman AdapT solvents have a strong track record for refinery use on every continent. MDEA-based technology has become the preferred option for refinery gas treatment because of the high-loading capability, minimal corrosion tendency, and high thermal and chemical stability.