Eastman expands its gas treatment portfolio with the addition of Eastman AdapT 110 for tail gas treatment

MDEA is an excellent choice for selective removal of H2S in the treatment of tail gas from a Claus-type sulfur recovery unit. Its inherent selectivity towards H2S, high capacity and low regeneration energy requirements have made it the default option for this application. Eastman AdapT solvents are based on MDEA, formulated to provide additional performance or operating benefits to the amine system. Eastman AdapT 110, the newest addition to the Eastman AdapT gas treatment portfolio, has been thoroughly tested and has demonstrated two key benefits versus generic MDEA in tail gas treatment:

1. lower energy consumption

2. deeper H2S removal

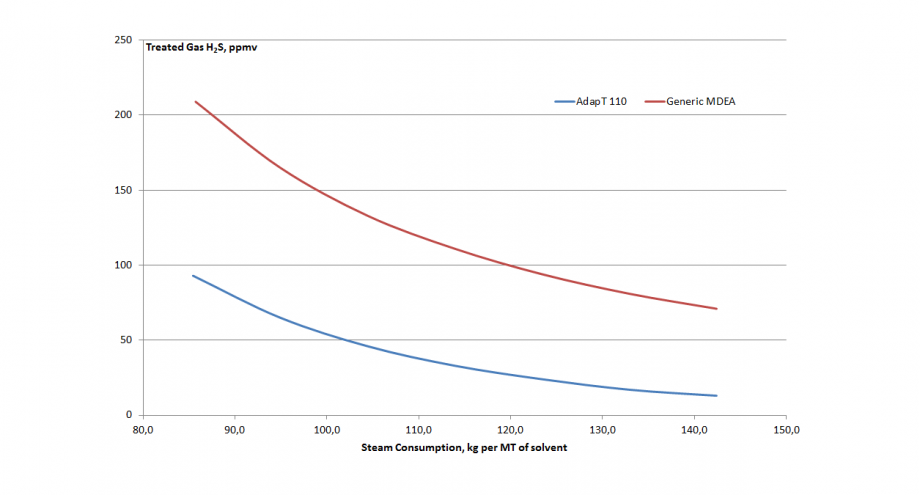

Both benefits can yield additional advantages such as higher selectivity, higher capacity, reduced equipment size and investment cost, as well as larger operating flexibility. The below graph illustrates these benefits for a typical refinery TGTU system:

Eastman AdapT 110 can handle a wide range of design and operating parameters, and has achieved H2S concentrations in the treated gas below 10 parts per million.

For engineering companies: In conjunction with its AdapT gas treatment portfolio, Eastman can help answer questions on areas such as appropriate process line up, equipment selection, energy optimization and design flexibility. To facilitate simulation, Eastman AdapT 110 is available in the Protreat® simulation software, enabling quick results when time is short.

For operators: Eastman can also help its customers to monitor solvent condition, maintain optimal plant operation and troubleshoot plant issues.

This newest addition to the Eastman AdapT family of products reinforces our dedication to meet individual gas treatment needs and give our customers true peace of mind.

For further information please contact the Eastman AdapT team.