Tailoring formulations

The importance of tailoring formulations according to application

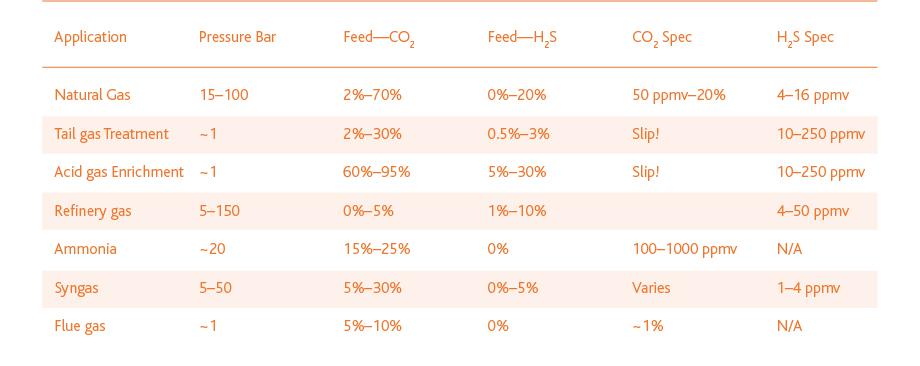

Depending on the source of the gas streams and the intended end use, the requirements for the acid gas removal unit can vary widely. While specifications for residual sulfur components are typically very stringent, H2S and other sulfur species are not present in every gas stream. The CO2 concentration may vary from nil to over 50 percent, and not every application necessitates complete removal. In addition, the gas stream may also contain traces of other organic species, such as mercaptans or carbonyl sulfide. Amines have a general affinity for acid gases because of the acid-base reaction, enabling efficient removal while absorbing inert components such as hydrocarbons, hydrogen, and nitrogen only minimally. However, the kinetics of that reaction vary widely depending on the type of amine and nature of the acid gas component. Through selection of the amine or combination of amines and plant design, the acid gas removal system can be optimized for its specific gas composition and treated gas application.

Another key parameter that impacts amine selection and plant design is the gas pressure. Higher pressures favor absorption, but amines are also capable of working efficiently at low feed pressure. In fact, in such conditions, amines are often the preferred technology because the chemical reactions enable an efficient process whereas other solutions, such as physical solvents or membranes, are strongly reliant on pressure for gas separation.

The applications for acid gas removal can be broadly categorized as follows:

- Natural gas processing

- Tail gas treatment

- Acid gas enrichment

- Refinery gas treatment

- Ammonia production

- Syngas treatment

In response to the varying challenges associated with these applications, Eastman has developed a portfolio of products that is tailored towards the various removal requirements. Final selection is ultimately based on a combination of processing conditions, process economics, robustness criteria, and environmental constraints. Eastman does not actively develop solvents for flue gas treatment, but our wide amine portfolio is available to technology developers and operators of flue gas CO2 removal plants.

Gas treatment specifications